What is up with those funny clips on our lug inserts?

Starting a brand-new drum business gave us the opportunity to re-think everything, and come up with solutions that just work better than the other products on the market, even down to the finest little details. First of all, I believe that all drum lug inserts should float/self-align. It’s non-negotiable, and prevents so many tuning and service issues.

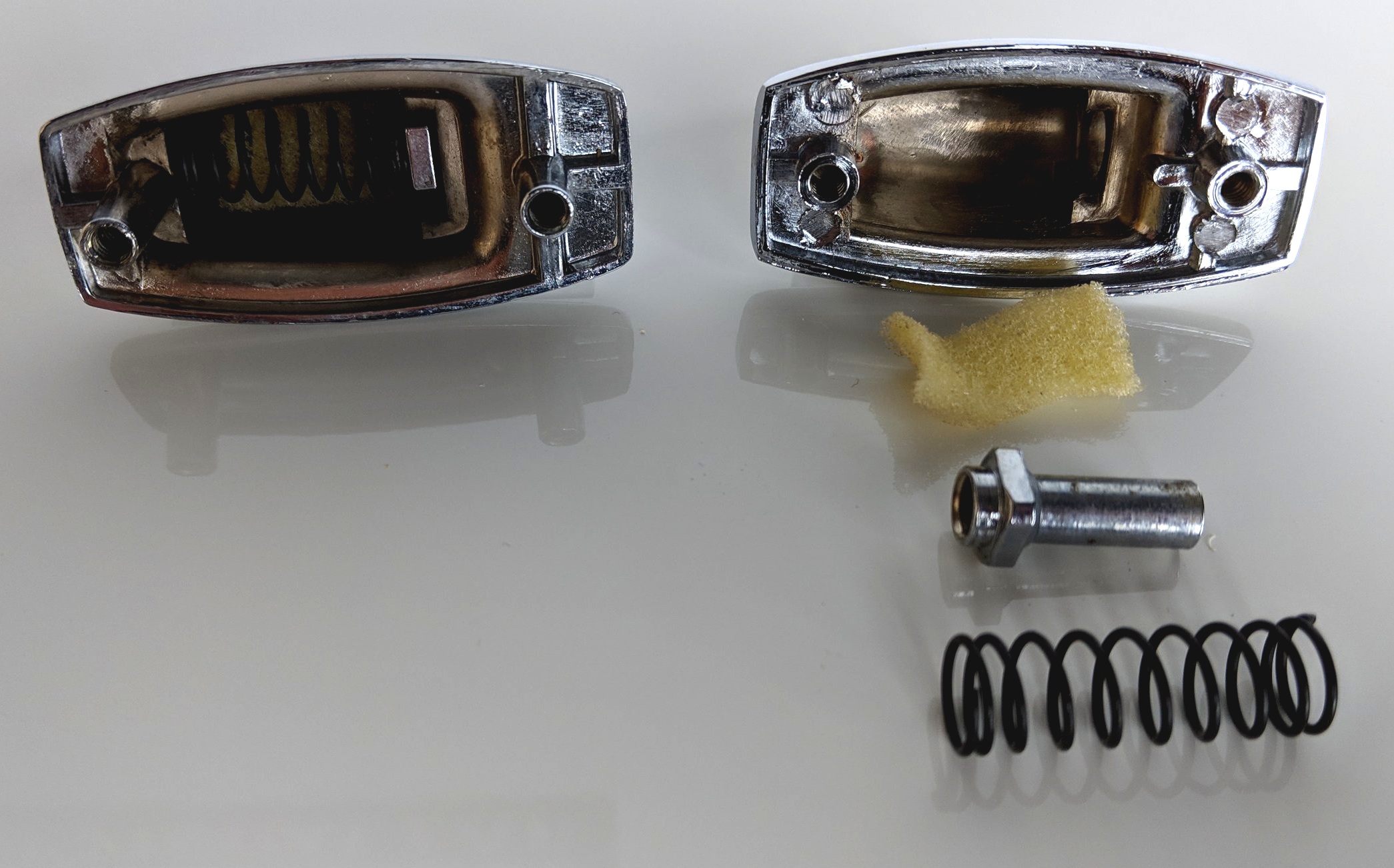

Back in the day, somebody invented the floating receiver (Hurrah!). Great stuff- now the tension rods threaded easier, and didn’t bind up when one was slightly out of alignment. To accomplish this, they used a spring to hold them in place, which unfortunately tended to rattle. So they added some foam to prevent this. Not the most elegant solution, but it worked (until the foam disintegrated, or was lost).

Then, someone figured out they could make them cheaper using a hunk of rubber instead of the spring. It works OK, but do you really want all of that energy absorbing rubber in your drums? What other acoustic instrument has 20 random pieces of rubber in it? It was a financial decision, not an acoustic one.

Which brings us to the INDe lugs. Fundamentally, I refused to use any vibration absorbing material on our drums, so rubber was out of the question (and spring rattle reducing foam). Also, I had this cool design for a lug with a monster arch in it, so there wasn’t really room for any of that crap anyway. So I found these cool little spring clips that let the insert float, but keeps the insert from falling out. No rattle, no damping materials. just a simple design that works, and holds our beautifully machined brass inserts in place. I know it is a tiny detail, and doesn’t matter to most drummers, but it matters to us, and is just another example of our no-compromise approach to sound and design.